So almost a week and a half of grueling late night work later we have an actual custom joystick together. My brother, John, and I worked on this baby after everyone else had gone to sleep in the wee hours of the night during our stay with them. Their smaller shed(actually tiny house) in their back yard provided us with some sound absorption as we routed into the night. Having an actual work space and the right tools made this task so much easier than I ever thought it would.

The plan was simple to start, shoot for a variation of this box from slagcoin.com. While we were just using the spare wood John had around we did use some MDF for the top panel. I think everything else was a pine, as we came to incur the random dent or two during the process. Considering we had the materials on hand it worked out for the best as I simply wanted a working box. My brother had better ideas and so we went about making it purty by going with miter joints rather than butt joints. Man what a pain in the ass did it become, but the end

product made it all worth it. The entire thing was a blast to do and quite the learning experience.

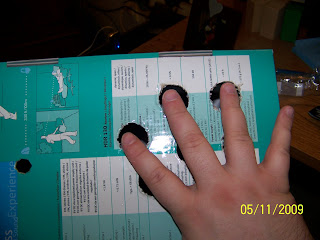

product made it all worth it. The entire thing was a blast to do and quite the learning experience.We used the basic dimensions from slagcoin and went with this layout for the top panel. Again big hands need large spaces to rest on. Most of the work was spent on the miter joints and getting the 'puzzle box' to fit together right. We cut the top panel out first and worked around that with the remaining joints. After a few days we came to the realization that our mdf top panel wasn't cut straight here and there....which led to so much fun throughout the project as it affected everything else from then on. We also made the mistake of not cutting out the acrylic and top panel together, so we had loads of fun matching them up later on. We did at least cut the button holes and joystick with the two together, so our initial acrylic cut matched the top panel perfectly(gap problems later). We had all intentions of using this one as a template so we could re cut the acrylic later on as we had a tendency to scratch the stuff easily. Acrylic aside, we went about routing out the joystick hole for the mounting plate.

You'll notice the nice Frankenstein look it ended up with.....apparently when you cut stuff upside down it doesn't quite fit things when they're right side up. Again who knew these kinds of things? We routed down the top and bottom for the mounting plate as well as a spot for the wire harness to fit through on the bottom. We put the top panel aside and began the work of fitting the miter edge puzzle pieces together along with the inside pieces.

An aside here, when I say "we" I really mean John, as he's much more proficient with woodworking than I'll ever be. Mostly I did a piss poor job of supervising, as we didn't think ahead quite a few times throughout. It did make it more entertaining though :).

After a few days of working to get the angles correct we stumbled on the issue of the bottom not fitting. Who knew slants were longer than straight edges? So we ended up with a nice gap to fill later, you can see it clearly from the picture above. While we began fitting the pieces together slowly another revelation hit us, we had fit the PCB in considering the top panel alone and not with the extra wood inside to adjust for the flush acrylic :( . We lost the bottom piece of wood for fit vs stability; after all what good is a stable box that can't hold its guts in? Next came the side buttons, which we couldn't fit in without having to route more into the top panel. Now it was possible to actually remove those buttons if needs be, vs leaving them forever in the wood. Another bit of miscommunication was the start button placement, not along the top with the other 2 but on the side for ease of use. That lead to the ugly cut you see on the left side of the box. Honestly I cared more about function than craftsmanship, though my brother did a damn fine job with these last minute changes and my heckling into the wee hours of the night.

At one point we realized our inside was too low(unable to fit the acrylic top in flush) as the wood we stripped to inset the top panel on was 1/8' short. That led to more stripping and redoing all the insider miter joints to fit with the existing outsides. Our gap in the bottom aside(putty does do wonders) it fit together rather well once we were finished. Routed the side buttons flush, thus they're sunk in nicely so you don't accidentally hit them. The start button is hit the most, reason for it to be on the right side as it feels natural to simply reach over and hit it after a match.

At the last minute before staining we decided to route out a hole for the mic. Yes we could have drilled a small mic jack hole and left it to be done with later. Yes I know that's a huge hole, but hell I just wanted it functional, thus we used the ms headphone and plugged it in and gauged from that. The two holes you see in the bottom(above pic) are for two brad nails we pin hammered in later that held the mic in place.

So feeling we were done we stained away. John did the first coat, a bombay mahogany polyurethane stain. We were down to the wire on time for the trip, so staining and poly at the same time was the quickest out. That and once again materials on hand go a long way. Eight hours later I gave staining a try, which clearly is not my strong suit. At this point I just wanted to get the guts in the thing and see how it played, so I'll take all the credit for the spotty stain job :) . After that had dried John put a coat of poly over it to give it some more shine. Some more hours later for drying and we went to set all the stuff in and give it a whirl. Low and behold another problem, we didn't account for the bolts in the mounting plate and the acrylic. So here we had our stain done and poly and we needed to route down the top panel to drop the stick down to account for the bolts.

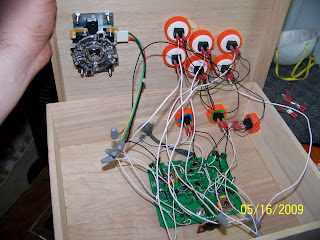

Let's just say we used some crazy unorthodox techniques during this process, but we got it done in the end heh. A short router job done.....well our batteries for the lantern ran out and we had to go to wally world and pick up more which was an awesome 40 minute wait in line.......and we went back to putting the guts in. Hahaha, did I mention we were working by latern at night? Ah good stuff heh. Anyways, after all we'd been through I didn't care at all at that point about a pretty wiring job. Some quick butt caps later and here's the inside and final product.

These were all taken once we'd gotten back home. We spent the rest of our time there enjoying family(and getting some actual sleep at night). As you can see, we didn't bother staining the inside, didn't see much point in it really. Once plugged in we played for a few hours that we regretted the next day. I don't think we slept but maybe one good night the entire trip heh. I just got around to cleaning the wiring up the other day, so here's a final version of the guts.

Not as clean as I would have liked, need to pick up some sleeves for all the wires. A huge improvement over the rush job just to play from before at least. I'm going to have to find some polycarbonate sometime as the acrylic plexi isn't very strong and bows in the middle easily. Once I've picked that up I'll re cut the top as well to fix the scratches and gaps. That and finally add feet to the bottom.

You can see the gap in the bottom of the acrylic here. That is actually the first piece we cut to use as a template. We botched every other piece we tried to cut and funny enough ended up with our work template on the top. Few cuts in it and the gap at the bottom(the unaccounted for angle vs straight distance lol). We went ahead and stained the top panel, though we didn't bother trying to make it look nice as art is going to cover that up in the end.

You can see the gap in the bottom of the acrylic here. That is actually the first piece we cut to use as a template. We botched every other piece we tried to cut and funny enough ended up with our work template on the top. Few cuts in it and the gap at the bottom(the unaccounted for angle vs straight distance lol). We went ahead and stained the top panel, though we didn't bother trying to make it look nice as art is going to cover that up in the end. If you've been following this, you'll know those buttons were picked out a long time ago. Clearly they don't fit with this stain. I'll eventually get around to ordering some other colors to match it and the art whatever that ends up being. All in all it's frigging awesome. The weight is perfect, as the only real heavy piece of wood in it is the MDF top panel. Routing out the joystick plate again actually put the height to what it should have been, so that turned out a boon. The mic works flawlessly, to which I've hot glued in the gaps to keep out dust, etc. I'll have to find some flat screws for the polycarbonate once I've picked that up.

If you've been following this, you'll know those buttons were picked out a long time ago. Clearly they don't fit with this stain. I'll eventually get around to ordering some other colors to match it and the art whatever that ends up being. All in all it's frigging awesome. The weight is perfect, as the only real heavy piece of wood in it is the MDF top panel. Routing out the joystick plate again actually put the height to what it should have been, so that turned out a boon. The mic works flawlessly, to which I've hot glued in the gaps to keep out dust, etc. I'll have to find some flat screws for the polycarbonate once I've picked that up.To sum up, it was one of the most fun and grueling experiences I've had on a project. Make sure whatever you do that you layout your groundwork on paper and your plan of attack. We ran into a lot of problems simply due to rushing and not enough forethought. Granted we were on a rush time schedule, so that certainly added to our stupid mistakes and not using our noggins. All that aside, for a first time job for the both of us I'm really pleased with the end results. John is going to work up some art sometime for it. When I get the polycarbonate in and fixed I'll re post with the end results. After all this I think I'll be taking a break for a bit before going after the next one. If you have any questions or laughs feel free to leave'm here.

And as always thanks goes out to my wife for enduring this venture, as well as my sister in law for putting up with our late night shenanigans.